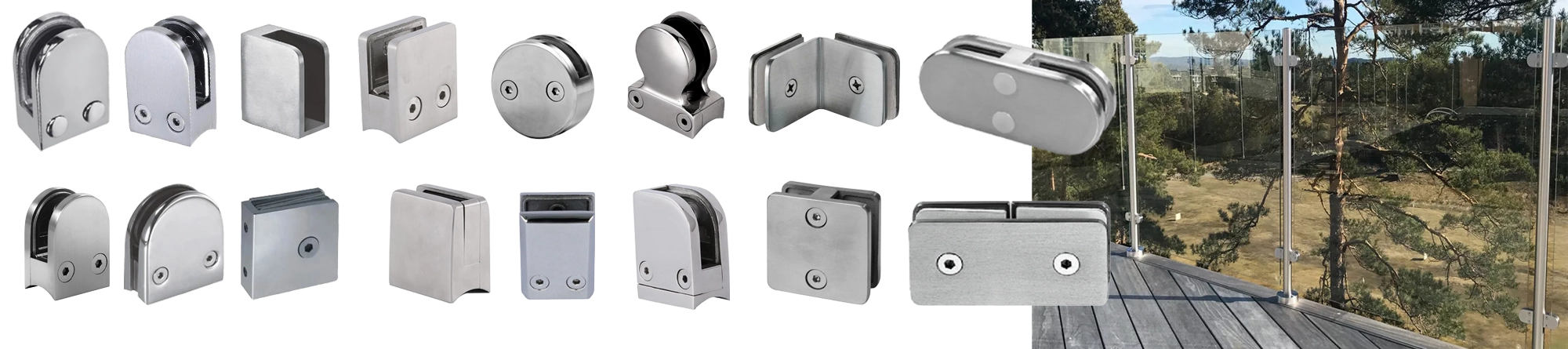

Investment Casting in Stainless Steel Glass Clamp

Investment casting, also known as precision casting or lost-wax casting, has been a pivotal manufacturing process for centuries, evolving from its ancient origins into a sophisticated technique with diverse applications. One of the modern marvels of investment casting is its application in the production of stainless steel glass clamps. This article explores the unique advantages and considerations of employing investment casting in the manufacturing of these essential components.

Advantages of Investment Casting in Stainless Steel Glass Clamps:

- Intricate Designs and Precision: Stainless steel glass clamps often require intricate designs to ensure a secure and aesthetically pleasing connection between glass panels. Investment casting excels in reproducing detailed and intricate features with high precision, allowing for the creation of complex shapes and intricate patterns that may be challenging to achieve through other manufacturing methods.

- Material Efficiency: Investment casting minimizes material wastage since it only utilizes the necessary amount of metal required for the final product. This efficiency is particularly beneficial when working with stainless steel, which can be a costly material. The process helps optimize material usage, making it a sustainable and cost-effective choice.

- Versatility in Stainless Steel Alloys: Stainless steel comes in various alloys, each with unique properties. Investment casting allows for the use of different stainless steel alloys, providing flexibility in selecting the material that best suits the specific requirements of the glass clamps. This versatility ensures the production of clamps with optimal corrosion resistance, strength, and durability.

- Consistency and Reproducibility: Investment casting ensures consistent and reproducible results, crucial for maintaining product quality and meeting industry standards. The process’s repeatability allows manufacturers to produce large quantities of stainless steel glass clamps with minimal variation in dimensions and performance.

Considerations and Challenges:

- Cost: While investment casting offers numerous advantages, it can be relatively more expensive than other casting methods. The initial tooling costs and the complexity of the process may contribute to higher upfront expenses. However, the long-term benefits, such as material efficiency and consistent quality, often outweigh the initial investment.

- Production Time: Investment casting involves multiple steps, including pattern creation, shell coating, and metal pouring, which may extend the overall production time. However, the precision and quality achieved through this method justify the slightly longer manufacturing duration.

Conclusion:

Investment casting has emerged as a game-changer in the production of stainless steel glass clamps, combining precision, versatility, and material efficiency. The advantages offered by this age-old technique contribute to the creation of durable, aesthetically pleasing, and high-performance glass clamps that meet the stringent requirements of modern architecture and construction. As technology continues to advance, investment casting remains a cornerstone in the production of intricate and finely crafted stainless steel components, ensuring the longevity and reliability of glass structures in diverse applications.

Investment casting, also known as precision casting or lost-wax casting, has been a pivotal manufacturing process for centuries, evolving from its ancient origins into a sophisticated technique with diverse applications. One of the modern marvels of investment casting is its application in the production of stainless steel glass clamps. This article explores the unique advantages and considerations of employing investment casting in the manufacturing of these essential components.