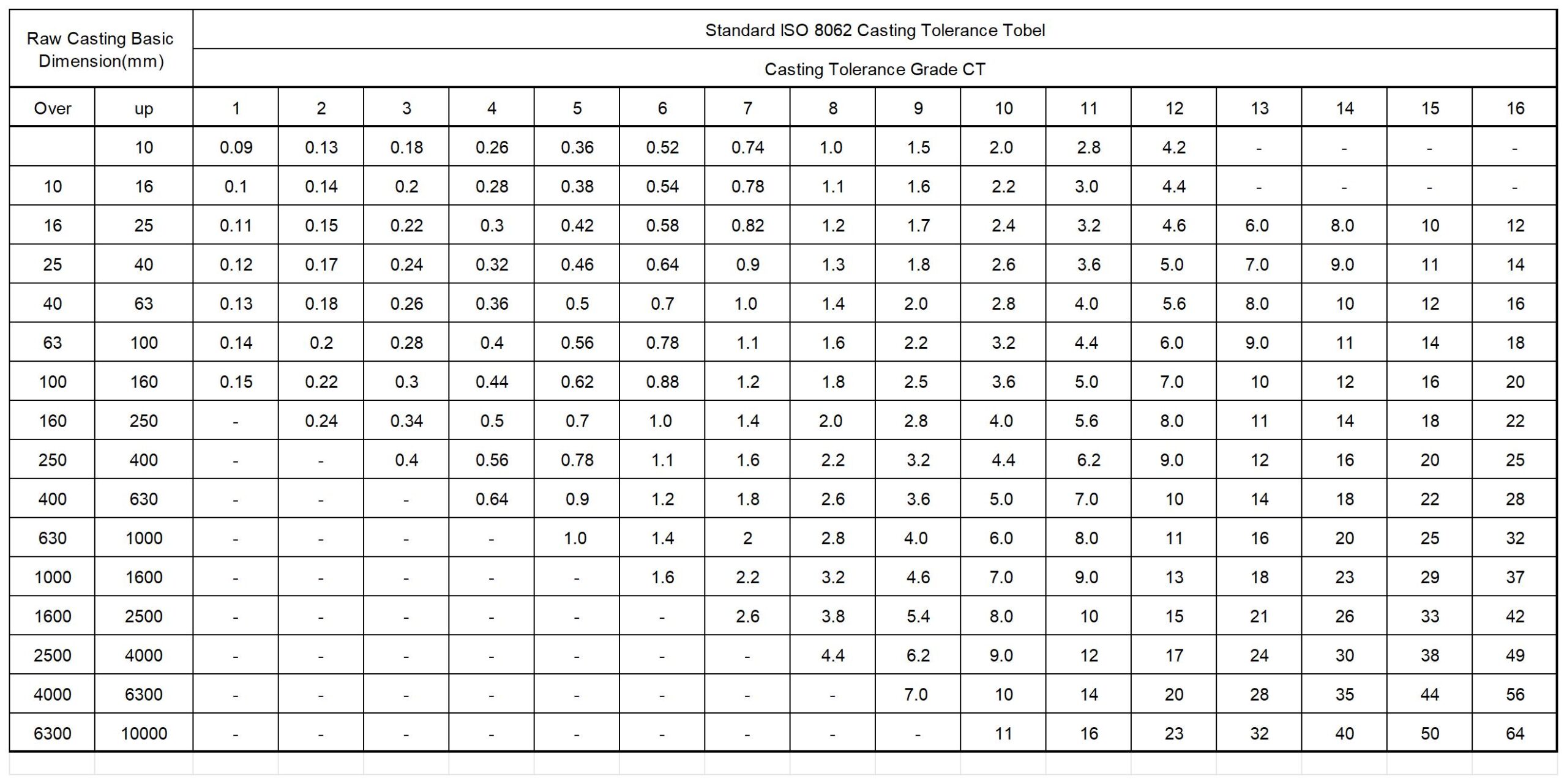

Investment Casting Tolerances

Investment casting tolerances refer to the allowable variation in the dimensions, geometry, surface finish, and other characteristics of the final cast part. These tolerances are essential to ensure that the part meets design specifications and functions as intended. Here are the main types of tolerances in investment casting:

1. Investment Casting Tolerances: Dimensional Tolerances

- Linear Tolerances: The allowable variation in straight-line dimensions such as length, width, and height. These tolerances specify the acceptable range of deviation from the nominal design values.

- Feature Size Tolerances: The allowable variation in the size of specific features like holes, slots, and bosses.

- Wall Thickness Tolerances: The permissible variation in the thickness of walls, which is critical for structural integrity, particularly in thin-walled castings.

- Hole Tolerances: These define the allowable variation in the size and shape of holes, which can affect fitting and assembly.

2. Investment Casting Tolerances: Geometric Tolerances

These tolerances focus on the shape, orientation, and location of features relative to each other.

- Flatness Tolerance: The allowable variation from a perfectly flat surface.

- Roundness (Circularity) Tolerance: The acceptable variation in the circularity of cylindrical or spherical features.

- Straightness Tolerance: The permissible deviation of a feature from a perfectly straight line.

- Parallelism: Specifies how closely two surfaces or features are parallel to each other.

- Perpendicularity: The allowable deviation of surfaces or features from being exactly perpendicular.

- Concentricity: The tolerance for how well the centers of two or more circular features align with each other.

3. Investment Casting Tolerances: Surface Finish Tolerances

- Surface Roughness: The smoothness of the cast part’s surface, typically measured by the roughness average (Ra). Investment casting can achieve smoother surfaces compared to other casting methods, but tolerances are still required to ensure the surface meets the functional or aesthetic needs of the application.

- Surface Defect Tolerance: The permissible level of surface defects such as porosity, inclusions, or rough areas that may need to be repaired or polished.

4. Investment Casting Tolerances: Positional Tolerances

- Location Tolerance: Defines the allowable deviation in the position of features like holes, slots, or bosses relative to a datum or another feature.

- Symmetry and Alignment: Tolerances that ensure symmetry or proper alignment of features, which is critical in assembly and functionality.

- Concentricity: Similar to geometric tolerances, concentricity also applies to how centered one feature is relative to another.

5. Investment Casting Tolerances: Shrinkage Tolerance

- Shrinkage Allowance: All cast materials experience some shrinkage during solidification and cooling. Investment casting typically accounts for shrinkage rates between 1.5% and 2%. This tolerance ensures that the mold is sized appropriately to produce a part with the correct final dimensions.

6. Investment Casting Tolerances: Angular Tolerances

- Angle Deviation: The allowable variation in the angle of features such as flanges, arms, or edges. Angular tolerances are measured in degrees and ensure that features like inclined surfaces meet the design specifications.

7. Investment Casting Tolerances: Draft Tolerance

- Draft Angle: In investment casting, a draft angle is required to ensure easy removal of the part from the mold. The tolerance here specifies the allowable variation in the draft angle, typically a small angle (e.g., 1-3 degrees) applied to the vertical surfaces.

8. Investment Casting Tolerances: Weight Tolerance

- Mass Deviation: Some applications require parts with specific weight limits. Tolerances can be applied to the overall mass of the part, especially in industries like aerospace where weight is critical.

9. Investment Casting Tolerances: Radial and Axial Tolerances

- Radial Tolerance: The allowable variation in the radius of cylindrical or circular features.

- Axial Tolerance: Tolerances on the alignment or positioning of features along the central axis, important in rotating parts or shafts.

10. Investment Casting Tolerances: Weldability and Repair Tolerances

- Repairable Defects: Investment castings sometimes allow for weld repairs to correct defects. Tolerances may define the size or type of defects that can be repaired through welding, and the areas where repairs are acceptable.

These tolerances ensure the cast parts meet both the functional and quality requirements of various industries, from aerospace to medical devices.